WoodVALOR

Dr Konstantinos Drousiotis

Senior Research Analyst

Alder BioInsights is pleased to be a member of the WoodVALOR consortium, a 3-year long CBE JU-funded project, with an estimated €3.5 mln allocated funding. The consortium brings 10 partners together to collaborate towards production and commercialisation of specialty chemicals from wood waste.

Specifically, the WoodVALOR project aims to transform contaminated post-consumer wood waste (WW) into high-value, sustainable bio-based products. It addresses the significant challenge of difficult-to-recycle wood waste, contributing to environmental restoration by converting low-value waste into high-performance materials and reducing reliance on petroleum-derived alternatives. Ultimately, WoodVALOR seeks to create circularity across multiple European value chains. This includes utilising waste streams from the mining and construction industries, as well as councils, to contribute to reforestation and produce key components of paints, coatings, sealants, and adhesives, while also recovering metals and minerals.

Participants

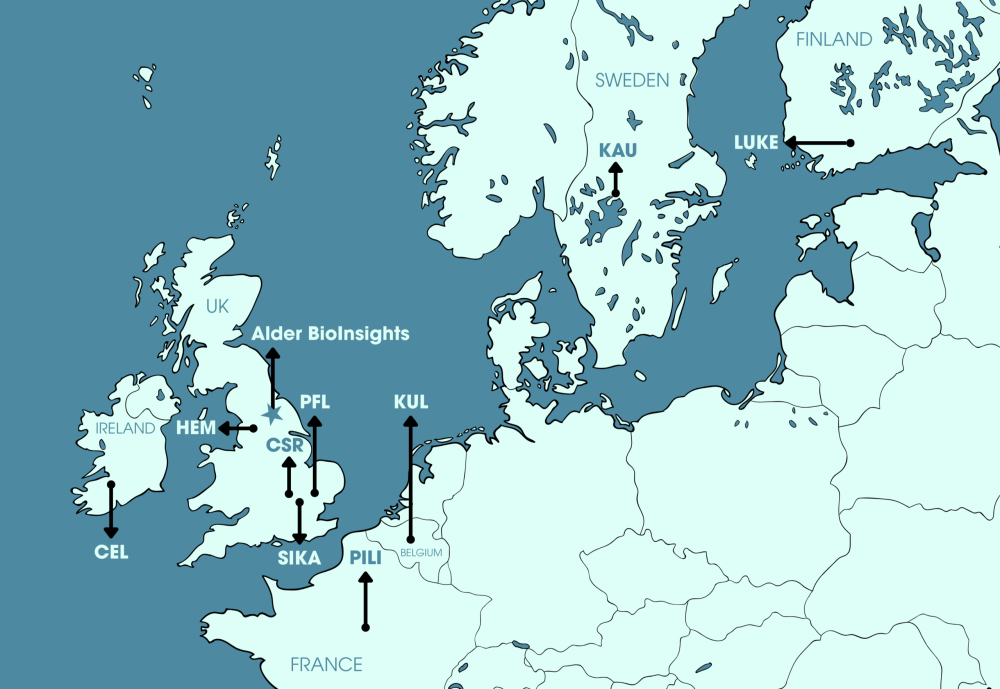

The WoodVALOR project brings together eleven participants from six countries. The coordinator is Linq Consulting and Management Ltd (LINQ) from the UK. The rest of the participants are mapped in Figure 1 based on the approximate location of their offices or facilities.

Figure 1. Participating companies and research institutions.

UK (apart from LINQ and Alder BioInsights) – PFL: PuriFire Labs, CSR: C-Source Renewables, HEM: Crown Paints Limited – subsidiary of Hempel Group, SIKA: Sika Limited;

Ireland – CEL: Celignis Limited;

Belgium – KUL: Katholieke Universiteit Leuven;

Sweden – KAU: Karlstads Universitet;

Finland – LUKE: Luonnonvarakeskus – Natural Resources Institute Finland;

France – PILI: Pili

Objectives

The consortium will attempt to valorise WW and produce components widely used in paints, coatings, sealants, and adhesives. Initially, the WW will be decontaminated and then chemo-enzymatically fractionated. Minerals and metals will be recovered from the treatment waste stream. Hemicellulose, cellulose and lignin fractions obtained from processing of decontaminated WW will be taken forward to produce the target specialty chemicals.

PFL will produce phenolic monomers from hydrothermal treatments of recovered lignin. CSR aims to generate lactic acid from glucose-rich hydrolysates by fermentation whereas PILI will employ the same methodology to produce indigo, blue, red, and yellow bio-based pigments. The obtained biobased lactic acid will be converted into acrylate esters by KUL through a novel two-step liquid-phase esterification-dehydration process. CSR will obtain fatty acids from microbial oils derived from yeast, which will in turn be utilised by CEL along with acrylic acid to ‘decorate’ the hemicellulose and phenolic fractions to finally yield binders and emulsifiers.

Eventually, HEM will use a generic emulsion polymer (latex) formulation to test the effects of the addition of acrylate ester monomers, novel biobased monomers and stabilisers. The goal of the polymerisation and formulations will be to achieve a viable acrylic latex and polymer harbouring the properties of in-house/ commercially available latexes. SIKA will mix the building blocks described above in their industrial formulations to obtain adhesives and sealants and thereafter test them under a pre-defined protocol.

Furthermore, LUKE will attempt to produce biochar by pyrolysis of organic waste or wood materials which will be tested for: improvement of soil fertility, water retention, microbial activity as well as novel applications such as carbon sequestration.

Wood Waste (WW) Feedstocks

The project will source wood waste feedstock from two primary suppliers, sorted into different grades (A, B, and C) for project activities. Both feedstock sources comply with “food first” and “cascading use” principles.

The grades of WW relevant to the project are the following:

- Grade A: Clean untreated wood, including virgin timber, offcuts from manufacturing, packaging waste, and scrap pallets.

- Grade B: Industrial wood waste, both untreated and non-hazardous treated wood, from construction, demolition sites, and solid wood furniture.

- Grade C: Municipal wood waste, a broader range of treated, non-hazardous wood like flat-pack furniture and DIY materials.

Our role

The first task involves identifying and mapping EU waste management regulations and frameworks associated with WoodVALOR’s deliverables. Potential bottlenecks due to non-supportive regulations will be identified in collaboration with project partners and the Stakeholder Board, culminating in policy recommendations.

Alder BioInsights will also be involved in employing a three-faceted approach to integrate the Safe and Sustainable by Design (SSbD) framework across the whole duration of the project, assessing safety and sustainability in a stage-gate format involving iterations. This task will necessitate frequent multi-stakeholder communication, and the results will hopefully inform ongoing policy development.